User Tools

Site Tools

Site Tools

Table of Contents

Power equipment

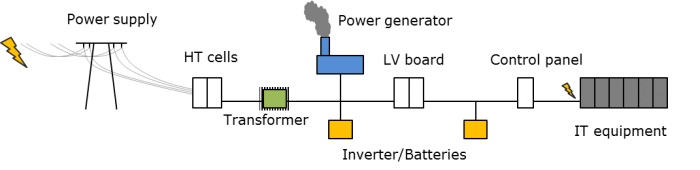

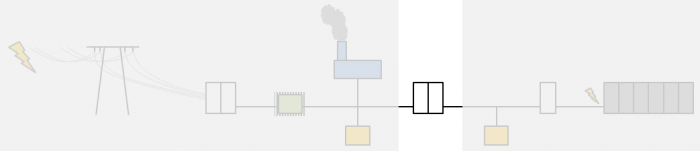

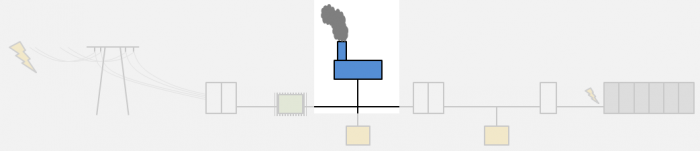

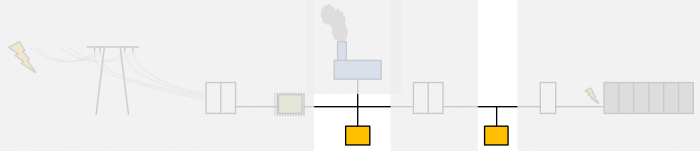

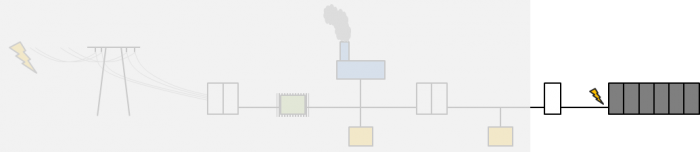

Standard datacenter topology can be similar to this:

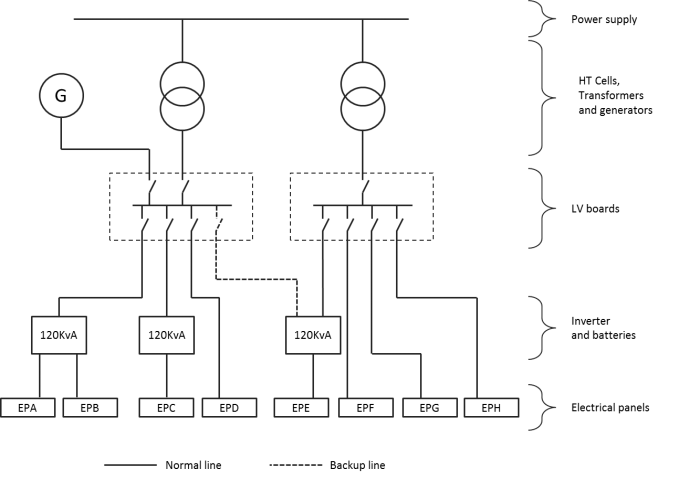

On this schema, it is possible to see the different levels of electrical distribution. Some installations are also equipped with backup lines for emergency backup of important equipment (dashed line). Some diagrams also represents last levels (after electrical panels), and could also include automatic backup system (generally thinner lines).

Some IT equipment are capable of having two PSU, i.e. two power sources, and switch from one to the other without interruption. Automatic source transfer systems are also available to provide equivalent security for IT equipment that are equipped with only one PSU.

High Voltage Cells

·

From http://www.engineering-mv.com/fr/wp-content/uploads/sites/2/2013/11/poste-transformation-hta-bt.gif

·

High voltage cells are often steel cabinet that regroups all HT elements (main circuit breaker, main circuit disconnector switch, etc., except HT transformer). The HV cells are directly connected between the power provider circuit and to the datacenter transformer. Cells can be used to totally isolate datacenter from main electricity.

Two main types of cells can be found in datacenter:

- Air isolated cell (for example, phases are separated by air). These cells are cheaper, but less reliable and use more space.

- SF_6 isolated cell (air is replaced by sulfur hexafluoride). These cells are more expensive, but more reliable and often used in datacenter where high reliability is important.

Transformer (HT)

·

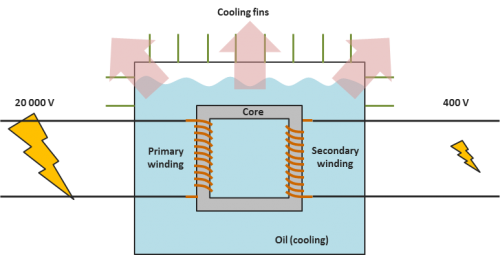

Transformer converting 20kV to 400V

·

·

Inside HT transformers (oil and transformer) http://light.dakotaelectric.com/Handbook/Pages1/Mineral%20Oil.aspx

·

·

Inside HT transformers (oil and transformer) http://light.dakotaelectric.com/Handbook/Pages1/Mineral%20Oil.aspx

·

An HT transformer (like all HT equipment) is extremely dangerous, do not enter a room with HT transformer in production, and keep 4m minimum distance with the equipment.

Transformers convert electrical current from high tension (HT) to low tension (LT) (from 20000 V to 230-400 V in France).

Conversion generates heat (power losses). This heat is evacuated through oil (natural convection) then through metal protection to air. Due to oil presence, a recovery tank is often below the transformer, in case of leaking.

Common flash point (transformer melt at flash point, due to oil evaporation) is around 140-150°c internal temperature.

LV Board (LT)

Only qualified electrician can operate or maintain a LV board, keep 50cm minimum distance with the equipment.

LV board is the link between power from HT transformers and the installation. It allows dispatching power on site and adapting tension on need. On major installation, multiple LV boards are used in common, and sometime in parallel to provide redundancy in case of failure.

Power Generator

Power generators are mainly huge diesel engines coupled with an alternator to provide emergency power supply in case of main power source failure. Most of the time, generator power is not enough to maintain compute node and only vital servers/network are maintained in production.

Due to starting time (few seconds in best cases), generator are often coupled with a way to store energy (batteries, kinetic accumulator, etc.) to overlap this time and provide continuous power in case of emergency (main power supply failure for example).

For some specific installation, power generators are the main power supply source.

It is advised to use power generators in charge (min 30%) at least every two month, for maintenance and problems detection. If not in charge oil will not liquefy enough, and piston will friction with combustion chamber and degrade it. Generator will become less and less powerful, and may break or not provide expected power during an emergency scenario.

Inverter and batteries

Only qualified electrician can operate or maintain inverter and batteries, keep 50cm minimum distance with the equipment.

Inverters are used to maintain a specific tension and frequency for connected equipment, independently of power source quality. It allows protecting equipment from small power cuts or tension/frequency variations from power source.

Most of the time, inverter are connected to a local power storage (batteries, flywheel, etc) in case of power source failure, in order to keep connected equipment in production for a small time (in order to solve power source problem or to start generators).

Inverters generate power losses, which turn into heat, and need to be cooled.

Some inverters require special manipulation when powering on many IT equipment at the same time to handle sudden load.

Batteries

Common inverters are linked to batteries to provide emergency power supply. Batteries need to be kept in a specific room, with temperature between 18°c and 22°c (may vary depending of the manufacturer).

Batteries require a lot of air regulated space to be stored, and needs to be replaces every few years (often 5 years).

Kinetic accumulator, flywheel

A kinetic accumulator is rotating mechanical equipment that is used to store kinetic energy. The amount of energy stored in is proportional to the square of its rotational speed.

Kinetic accumulators are more expensive than batteries, but require much less space, and if correctly maintained, can be operated for more than 20 years without replacement.

Due to speed variation during discharge, kinetic accumulators need to be coupled to an inverter to provide expected power frequency.

It is recommended to use vertical axis kinetic accumulator instead of horizontal axis, for equipment durability and reliability.

Electric control panel (LT)

Electric control panel are often located in computer room. These are the last equipment before the computer PSU.

- If connections are not protected (electrical cables not behind protections), only qualified electrician can operate or maintain a LV board, keep 50cm minimum distance with the equipment.

- If connections are protected (IP22 or IP2X), authorized user can reset a circuit breaker only once (if it fail, do not reset it again).

Disjunctions can occur if Electric control panel is not cooled enough.

Cables and plugs

When not correctly dimensioned, cables can overheat, causing failures and fires. A thermal camera is an excellent tool to identify hot points.