User Tools

Site Tools

Site Tools

Table of Contents

Datacenter cooling equipment

Pipes

Pipes transport coolant liquid in datacenter.

A good approach is to limit pipes lengths, sharp angles or angular shapes. The bigger the radius, the less pressure drop but cost and space is rapidly limiting.

Some datacenter paint pipes with colors according to their role. In large datacenter with many circuits, colors can help rapidly identify circuits. Be careful not to use reserved colors (like red for fire extinction systems, yellow for gas, etc.).

Pumps

Pumps provide coolant liquid pressure and generate flow in pipes.

A best practice is to have at least N+2 pumps. When one fail or is in maintenance, there is still one backup.

Pumps suffer from cavitation, particles impacts, fluid viscosity or galvanic corrosion. They require regular maintenance and inspection.

Good indicators are external temperature, sound, vibrations, and pressure differential between input and output. Monitoring pressure differential and comparing regularly this pressure with initial pressure can help detect abnormal behavior.

Evaporator / Humidifier

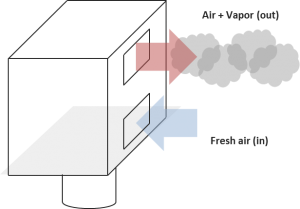

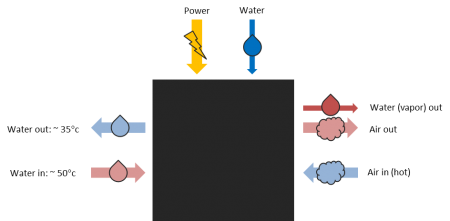

Schema

·

Common humidifier producing vapor, fixed on wall.

·

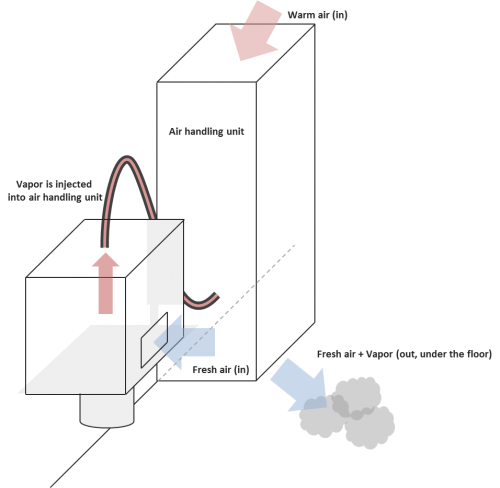

·

Humidifier coupled with and air handling unit.

·

Humidifiers are often hot equipment, with hot surfaces, and hot water. Hot vapor can spread when opening and cause dangerous burns. Manipulate with care. In case of vapor burn, immediately spread cold water during minimum 5 minutes on the burned skin.

General information

Humidifiers are simple elements that heat water to evaporation and push this vapor into computer room to raise room humidity. However, they should be correctly placed in the room, to prevent direct vapor aspiration by air handling unit or dehumidifier. A commonly used solution is to push vapor under the floor when air handling unit also push fresh air under this floor.

Humidity probe position in the room is also important and regulation should be made according to this position.

Humidifiers are sometime coupled with air handling units (inside or outside and connected with a pipe).

How it works

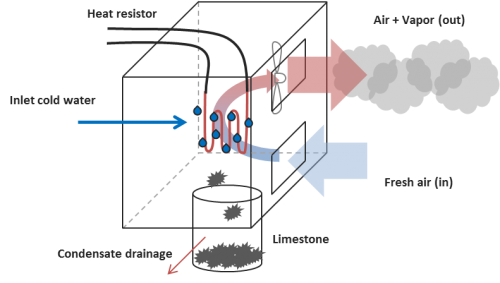

·

Humidifier inside, heat resistor and water vaporization.

·

Optimization

There are not a lot of optimization available for this equipment. However, one should keep this into account: except in specific cases, evaporator only have regulator role and should only “wake up” when exterior air goes into the IT room. An intensively used evaporator (lot of maintenance, evaporator always working, etc) means IT room air and hygrometry are very badly managed. The manager should check regulation and probes, and use the psychometric chart to modify the IT room air humidity ratio depending of desired air temperature and cold water temperature (see in Basis of this section, psychometric chart).

Maintenance

Humidifiers need very regular maintenance (especially if room hygrometry is badly managed), mainly due to limestone accumulation. It is recommended to have a large bucket somewhere around to facilitate maintenance or emergency leak.

Humidifiers also need specific evacuation for condensed water. It is recommended to protect floor from water under the humidifiers.

Note: MK5 humidifier access code is 8808 (press up and down simultaneously before).

Air Handling Unit (Dehumidifier)

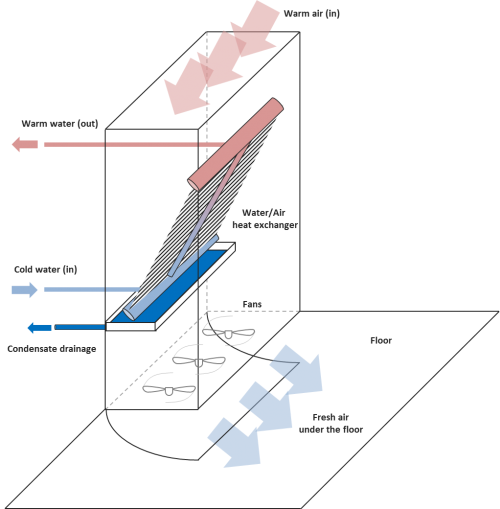

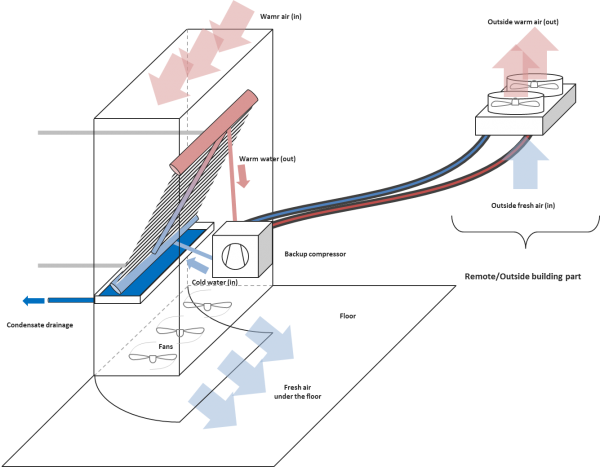

·

Standard air handling unit, with inlet on top and outlet under the floor.

·

·

Air handling unit with backup compressor in use in case of cold water supply failure.

·

General information

Air handling units are also often called condensing unit.

Air handling units are robust and simple equipment but require regular inspection.

Air handling units working in a badly calibrated air environment and cool water combination will represent a major energy loss.

Maintenance

Air Handling units should be be inspected monthly. Common issues are:

- Water condensing in surface of the heat exchanger or pipes (means possibly something wrong in room regulation).

- Corrosion or leaks (investigate under unit).

- Condensing water recuperator obstructed.

- Fan not working, or generating noise/vibrations.

- Air inlet filter obstructed.

If air handling unit is equipped with security system (compressor):

- Test blocking cold water inlet, and ensure compressor is working. Let it run few hours and reopen water supply to resume normal operation.

If air handling unit do not operate normally, one thing to investigate is also probes values. A temperature or humidity probe failing may result in various unexpected behavior.

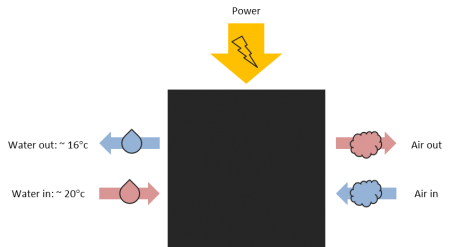

Chillers

Schema

General information

Circuit water goes in warm and goes out cold. The chiller uses air to cool circuit water. There are no physical exchanges between circuit water and air, circuit water is always in a closed circuit.

The amount of power consumed is significant (fans, compressors, pumps, etc.). COP is often between 3 and 4.

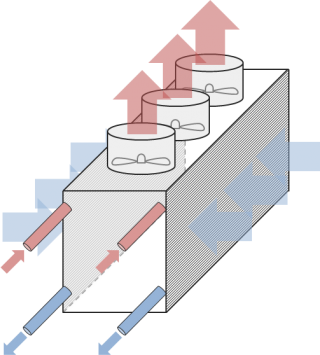

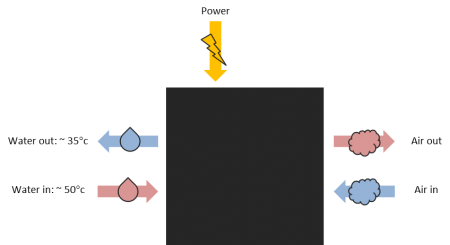

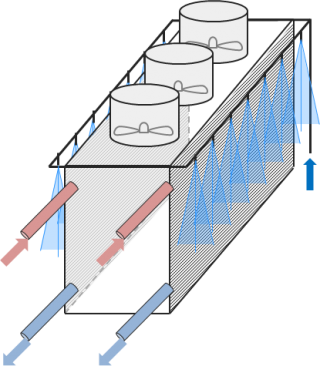

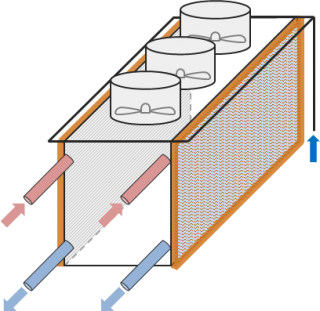

Dry/Adiabatic coolers – Dry mode

Schema

·

Dry cooler, also called free cooling cooler.

·

General information

In dry mode, the cooler only use “forced” free-cooling. Circuit water goes in hot and goes out warm. The cooler uses air to cool circuit water. There are no physical exchanges between circuit water and air, circuit water is always in a closed circuit.

The amount of power consumed is small (only fans are used).

How it works

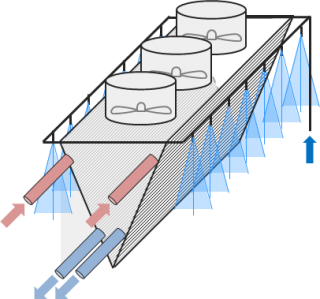

Dry/Adiabatic coolers – Adiabatic mode

Schema

·

Common Adiabatic cooler

·

·

V shaped adiabatic cooler

·

·

Cardboard adiabatic cooler

·

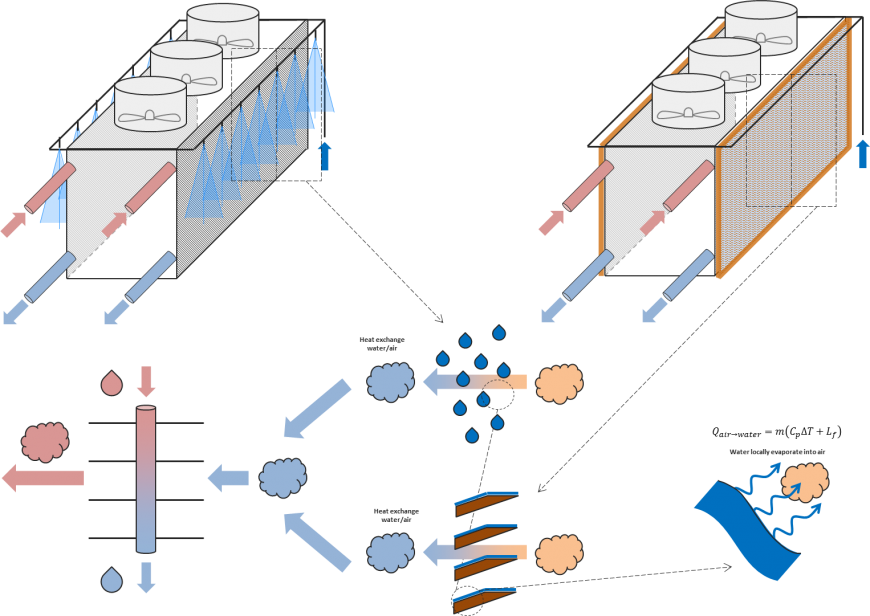

General information

How it works

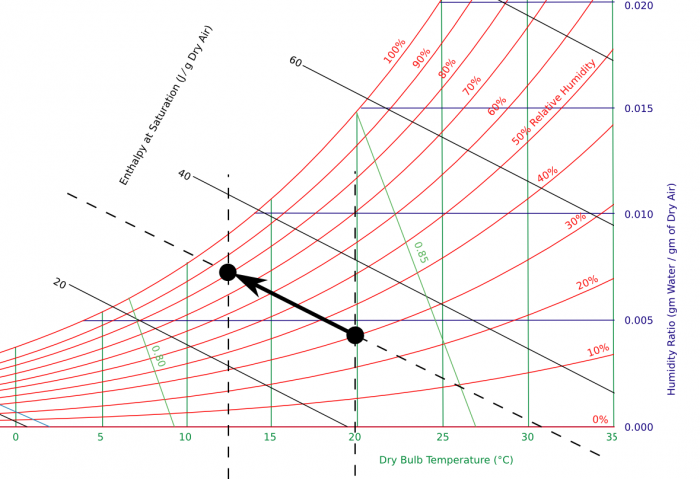

When air goes through water droplets flux, a part of water evaporates. Heat needed to evaporation is taken from air, cooling it. Because heat is locally exchanged, without interactions with the environment, this phenomenon is adiabatic and follows the constant enthalpy curves of humid air chart.

In this example, air at 20°c and 30%H is cooled using water droplets. It’s humidity and mass of water per mass of gas increase and follow a constant enthalpy curves, to reach 80%H. Its temperature is then 12.5°c.

Cooling towers

Heat (25°c to 45°c) and water recirculation in cooling towers is a good environment for Legionella bacteria proliferation. Extreme care should be taken when using cooling towers in production. Regular water analysis should be done.

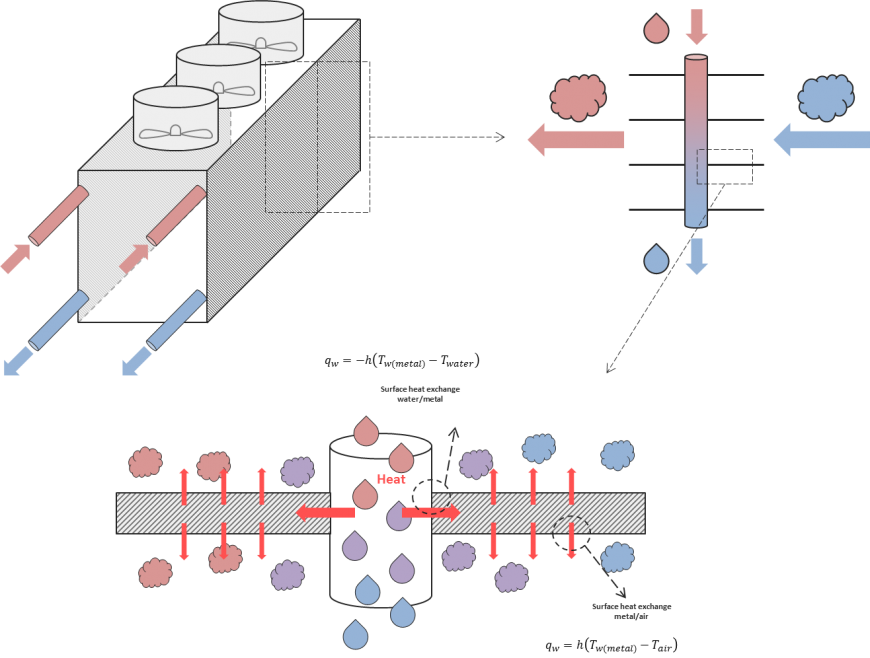

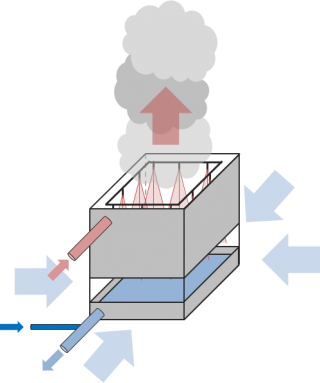

Schema

·

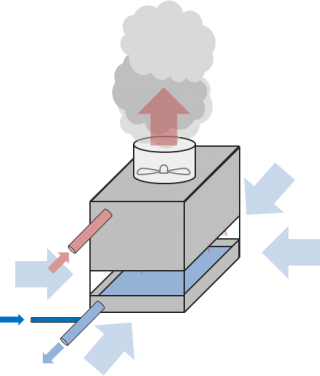

Standard cooling tower (natural convection)

·

·

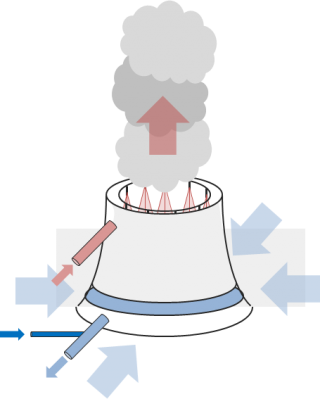

Forced convection cooling tower (Fans can also be at bottom)

·

·

Round shape cooling tower

·

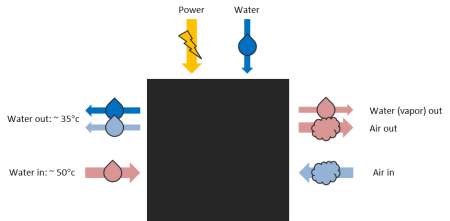

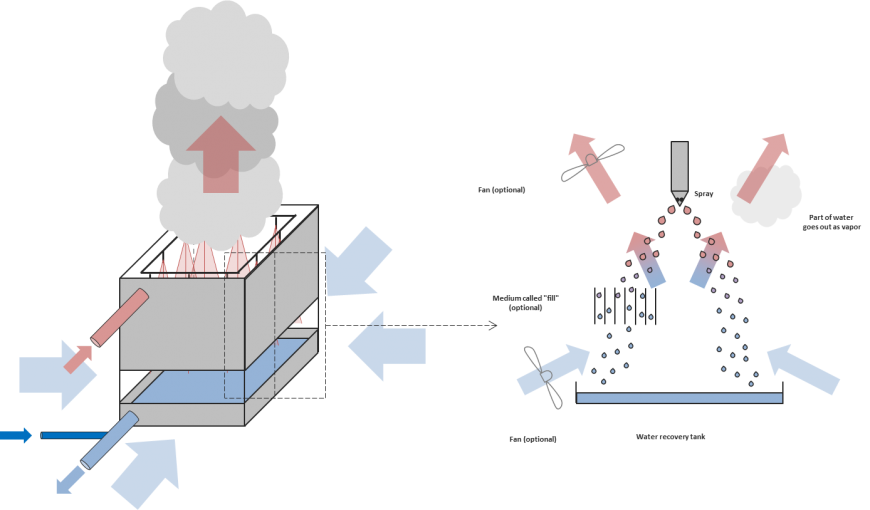

General information

Circuit water goes in hot and is spray and mixed with in air inside the tower. A part of this circuit water is vaporized and goes out with hot air. To compensate this circuit water loss, external water is mixed with warm circuit water injected back to datacenter.

The amount of power consumed is small (only fans and small pumps are used). The amount of water used can be medium to significant.